In industrial refrigeration, efficiency and reliability are non-negotiable—especially when working with ammonia (NH3), a refrigerant prized for its performance and eco-friendliness. At the heart of these systems, heat exchangers play a pivotal role in maintaining optimal temperatures while minimizing energy consumption. For businesses seeking to balance upfront costs with long-term value, refurbished heat exchangers from leading brands like Alfa Laval and SWEP offer a compelling solution. In this blog, we’ll explore how pre-owned units from these manufacturers deliver efficiency, durability, and cost savings for ammonia-based refrigeration systems.

Why Heat Exchangers Matter in Ammonia Refrigeration

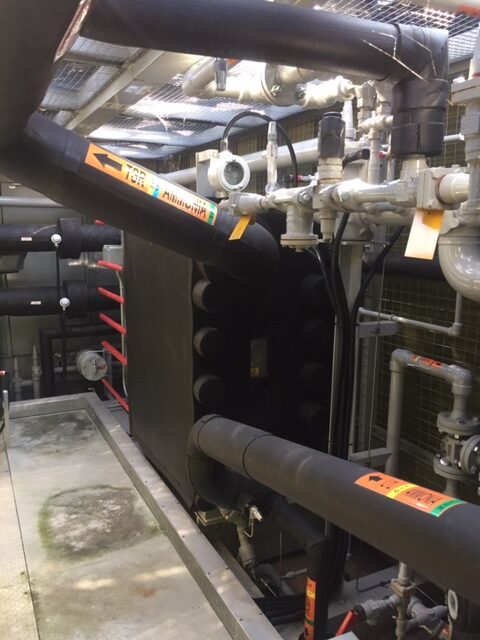

Ammonia’s thermodynamic properties make it ideal for large-scale cooling, but its corrosive nature demands equipment engineered to withstand harsh conditions. Heat exchangers facilitate the transfer of thermal energy between ammonia and other fluids, ensuring systems operate efficiently without overheating or energy waste. Key functions include:

- Condensing: Converting ammonia vapor back to liquid.

- Evaporating: Absorbing heat to cool industrial spaces or processes.

- Energy Recovery: Reusing waste heat to reduce overall power consumption.

A well-designed heat exchanger maximizes system efficiency, lowers operational costs, and extends equipment lifespan. However, new units can strain budgets. This is where refurbished heat exchangers shine—combining proven performance with significant cost savings.

Alfa Laval vs. SWEP: Comparing Refurbished Heat Exchangers

Both Alfa Laval and SWEP are industry leaders known for innovation and durability. Here’s how their refurbished models stack up in ammonia systems:

Alfa Laval: Precision Engineering for Heavy-Duty Applications

Alfa Laval’s plate heat exchangers are synonymous with reliability in demanding environments like food processing, chemical plants, and cold storage facilities.

Key Advantages of Refurbished Alfa Laval Units:

- Corrosion Resistance: Titanium or stainless steel plates resist ammonia degradation.

- High Thermal Efficiency: Tight plate spacing ensures rapid heat transfer, reducing energy use.

- Modular Design: Easy disassembly for cleaning or repairs, minimizing downtime.

Refurbished Alfa Laval exchangers are ideal for facilities requiring robust performance under continuous operation. Look for units with upgraded gaskets or plates to ensure longevity.

SWEP: Compact Solutions for Versatile Needs

SWEP specializes in brazed plate heat exchangers (BPHEs), offering compact, lightweight designs perfect for retrofitting older systems or space-constrained facilities.

Key Advantages of Refurbished SWEP Units:

- Space Efficiency: Smaller footprint without compromising capacity.

- Leak-Free Construction: Brazed copper or nickel joints eliminate gasket failure risks.

- Cost-Effective Maintenance: Fewer moving parts reduce long-term servicing costs.

Refurbished SWEP exchangers excel in breweries, dairy plants, and HVAC applications where adaptability and energy savings are priorities.

Economic & Environmental Benefits of Refurbished Heat Exchangers

Investing in pre-owned Alfa Laval or SWEP heat exchangers isn’t just a budget-friendly choice—it’s a strategic one. Here’s why:

- Upfront Cost Savings: Refurbished units cost 40–60% less than new models, freeing capital for other upgrades.

- Sustainability: Reusing equipment reduces manufacturing waste and carbon footprints, aligning with circular economy goals.

- Proven Reliability: Older models from trusted brands have decades of field-tested performance, ensuring they meet industrial demands.

Ensuring Quality in Refurbished Heat Exchangers

Quality is paramount when purchasing pre-owned equipment. At RefrigerationEquipment.net, our refurbishment process includes:

- Rigorous Inspection: Checking plates, gaskets, and joints for wear or corrosion.

- Performance Testing: Verifying thermal efficiency under ammonia-specific conditions.

- Component Upgrades: Replacing seals, gaskets, or plates with modern, ammonia-resistant materials.

This ensures every refurbished unit performs like new, backed by warranties for peace of mind.

Upgrade Your Ammonia System—Smartly and Sustainably

Don’t let high costs delay essential upgrades. Explore our inventory of refurbished Alfa Laval and SWEP heat exchangers to enhance efficiency, reduce expenses, and support sustainability.

📞 Call Us at (555) 123-4567 for personalized recommendations!

By choosing refurbished heat exchangers, you’re not just cutting costs—you’re investing in equipment that keeps your operations running smoothly and sustainably. Let us help you achieve peak performance without the premium price tag.

Refrigeration Equipment Professionals (REP) is a trusted supplier of industrial refrigeration systems and surplus/used equipment, offering compressors, chillers, condensers, evaporators, ice machines, freezers, coolers, pumps, motors, complete plants, and services like purchasing, refurbishing, shipping, export crating, and storage/consignment support. With 25+ years of experience and clients across North America, Latin America, the Middle East, and Asia, we deliver reliable, cost-effective refrigeration solutions worldwide.