Let’s face it – your used ammonia compressor isn’t getting any younger. But unlike that gym membership you swore you’d use, with proper care these industrial workhorses can keep performing well past their expected retirement age. At RefrigerationEquipment.net, we’ve seen Mycom, Vilter, and Frick compressors outlive the careers of the technicians who installed them (and several company reorganizations).

Here’s how to keep your used ammonia compressor running smoother than a politician’s promises during election season.

The Daily Grind: Routine Maintenance Must-Dos

1. Oil Changes Aren’t Just for Your Car

Your compressor’s oil is its lifeblood – neglect it, and you’ll be shopping for a new compressor faster than you can say “catastrophic bearing failure.” For Mycom, Vilter, and Frick compressors:

- Change oil according to manufacturer specs (typically every 3-6 months)

- Use only recommended oil grades – this isn’t the time to experiment with bargain bin specials

- Monitor oil filters like a hawk watching its nest

Pro tip: If your oil looks like a Starbucks dark roast, it’s way past due for a change.

2. Keep It Clean, You Animal

Dirt and ammonia compressors mix about as well as oil and water (which, coincidentally, is another bad combination for your system). Regular cleaning should include:

- Blowing out condenser coils quarterly

- Keeping the compressor room free of debris

- Wiping down external surfaces (yes, even if it’s hidden in the back corner no one sees)

Remember: A clean compressor is a happy compressor, and happy compressors don’t unexpectedly fail at 2 AM on a holiday weekend.

The Monthly Checkup: Catching Problems Early

3. Vibration Monitoring – The Canary in the Coal Mine

Excessive vibration is your compressor’s way of saying “Hey dummy, something’s wrong!” For all major brands:

- Invest in basic vibration monitoring equipment

- Establish baseline readings when the unit is healthy

- Investigate any changes immediately

Think of it like your compressor’s version of a check-engine light, except ignoring it could cost you five figures instead of a $98 diagnostic fee.

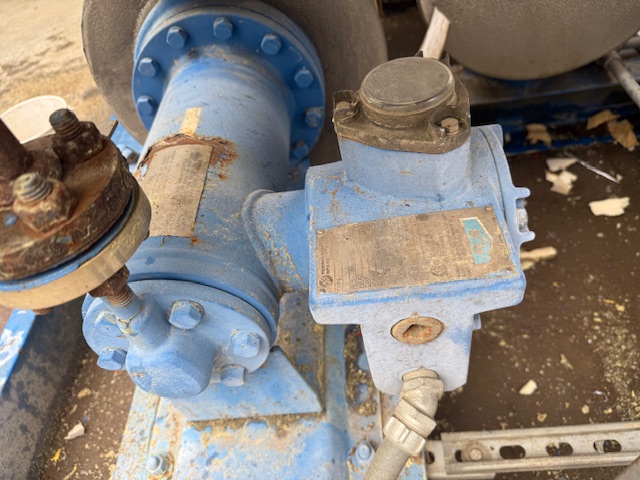

4. Leak Detection: Find It Before OSHA Does

Ammonia leaks are bad for business, bad for your insurance premiums, and really bad for your nose hairs. Monthly checks should include:

- Electronic leak detector sweeps

- Visual inspections of fittings and connections

- Monitoring for unexpected increases in refrigerant usage

Bonus: Finding and fixing small leaks promptly will save enough money in lost refrigerant to buy lunch. Maybe even a nice lunch.

The Annual Spa Treatment: Major Maintenance

5. Valve Maintenance – The Heart of the Matter

Compressor valves take more abuse than a rental car at a demolition derby. Annual maintenance should include:

- Inspection and possible replacement of valve plates and springs

- Checking piston rings for wear

- Verifying proper clearance on all moving parts

This is where having OEM parts from the original manufacturer (Mycom, Vilter, or Frick) pays dividends in performance and longevity.

6. Electrical System Checkup

Electrical components age about as gracefully as milk left in a hot car. Annual electrical maintenance should cover:

- Tightening all connections (vibration loves to loosen them)

- Testing motor windings

- Verifying proper operation of all safety controls

Pro tip: If you see electrical tape being used as a “permanent” fix, it’s time for professional help.

When to Call in the Professionals

Even the most diligent maintenance program can’t prevent all issues. Warning signs you need expert help include:

- Unexplained increases in energy consumption

- New or unusual noises (beyond the normal industrial symphony)

- Oil contamination that keeps recurring

- Performance degradation that routine maintenance doesn’t fix

The Used Compressor Advantage

Here’s the beautiful part – a well-maintained used Mycom, Vilter, or Frick compressor can deliver 80% of the performance of a new unit at 30% of the cost. At RefrigerationEquipment.net, we specialize in:

- Quality inspected used ammonia compressors

- OEM parts for major brands

- Expert advice on maintenance and troubleshooting

Your Next Steps

- Shop our selection here

- Sell us your old unit if you’re upgrading

- Contact our experts for maintenance questions or parts needs

Remember, with proper care your used ammonia compressor might just outlast your career. And if it doesn’t, we’ll be here to help you find its replacement – preferably before it fails catastrophically during your next big production run.

Refrigeration Equipment Professionals (REP) is a trusted supplier of industrial refrigeration systems and surplus/used equipment, offering compressors, chillers, condensers, evaporators, ice machines, freezers, coolers, pumps, motors, complete plants, and services like purchasing, refurbishing, shipping, export crating, and storage/consignment support. With 25+ years of experience and clients across North America, Latin America, the Middle East, and Asia, we deliver reliable, cost-effective refrigeration solutions worldwide.