Designing or overhauling an industrial refrigeration system is a complex task, especially when balancing performance, reliability, and budget. For experienced buyers, engineers, and consultants, sourcing used industrial refrigeration equipment is often a strategic decision rather than a cost-cutting one.

When done correctly, integrating pre-owned compressors and condensers from trusted manufacturers can deliver the same operational outcomes as new equipment, while significantly reducing capital expenditure and lead times. The key lies in system-level thinking, not component-by-component purchasing.

Why System Integration Matters More Than Individual Components

Compressors and condensers do not operate in isolation. Their interaction defines system efficiency, stability, and long-term reliability. A mismatch between components can lead to higher energy consumption, excessive wear, or operational instability.

Successful system integration requires alignment across:

- Capacity and load profiles

- Operating pressures and temperatures

- Control strategies and sequencing

- Oil management and heat rejection

- Physical layout and piping design

This is why system design must come first, with component selection supporting the broader objective.

Integrating Pre-Owned Compressors into Existing or New Systems

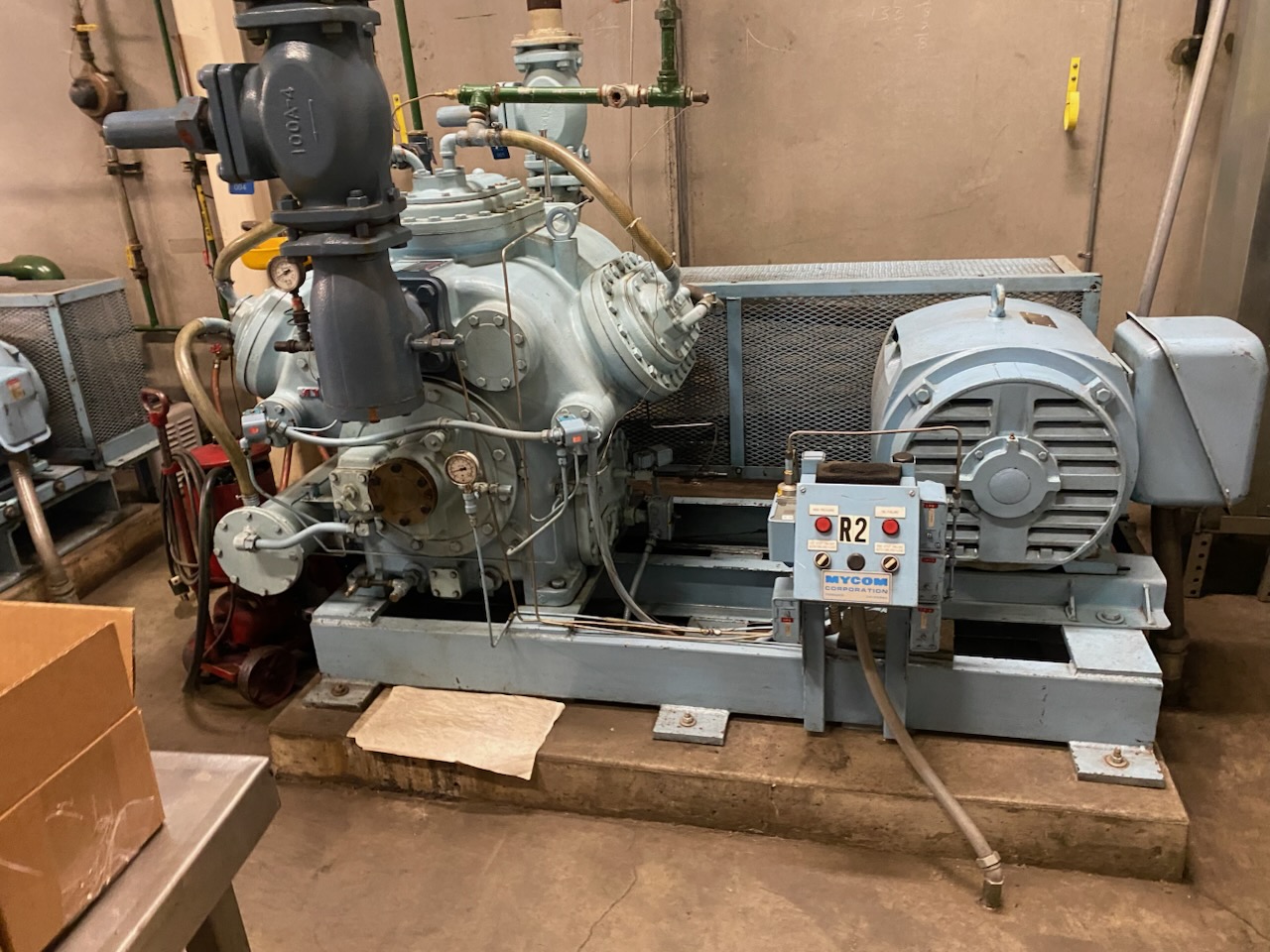

Used compressors are often the centerpiece of system retrofits or rebuilds. Whether screw or reciprocating, their suitability depends on how well they match system demands.

Key considerations include:

- Refrigerant compatibility, particularly for ammonia systems

- Capacity alignment with peak and part-load requirements

- Control system integration and automation compatibility

- Mechanical condition and remaining service life

Compressors from established manufacturers such as Frick, Mycom, GEA, and Howden are frequently chosen because their designs are well documented and proven across decades of industrial use.

Selecting the Right Pre-Owned Condenser for Heat Rejection

Condensers play a critical role in system efficiency. Even the most advanced compressor cannot perform optimally if heat rejection is insufficient or inconsistent.

When integrating pre-owned evaporative condensers, buyers should evaluate:

- Heat rejection capacity under site-specific conditions

- Airflow and water distribution performance

- Structural integrity and corrosion resistance

- Compatibility with existing piping and layout

Manufacturers like Evapco and BAC are commonly selected due to their strong thermal performance and durability, making them reliable choices in system-level designs.

The Advantage of Pairing Used Compressors and Condensers

One of the most effective ways to control cost and lead time is to source both compressors and condensers as part of a coordinated solution. When components are evaluated together, integration risks are reduced.

Benefits of a coordinated approach include:

- Better performance matching across the system

- Simplified installation and commissioning

- Reduced compatibility issues

- Streamlined maintenance planning

This approach is especially valuable for facilities upgrading aging systems or expanding capacity without rebuilding from scratch.

Inspection and Testing Are Non-Negotiable

The success of a system built with used industrial refrigeration equipment depends entirely on inspection and validation. Each component must be evaluated not only on its own merits, but also on how it will perform within the system.

Critical inspection elements include:

- Mechanical integrity and wear assessment

- Verification of operating parameters

- Electrical and control system checks

- Performance testing under controlled conditions

Thorough inspection ensures that pre-owned components meet operational expectations before installation, not after startup.

Designing for Flexibility and Future Growth

One advantage of building systems with used components is flexibility. Modular system design allows facilities to adapt as production needs change.

Well-integrated systems can:

- Accommodate future capacity expansions

- Allow phased equipment upgrades

- Reduce risk during system transitions

- Extend overall system life

This flexibility is particularly attractive to operators managing evolving operational demands.

Why System-Level Expertise Matters

Integrating pre-owned compressors and condensers is not about finding the lowest-priced components. It is about understanding how each piece contributes to system performance, efficiency, and reliability.

Suppliers with deep industrial refrigeration expertise can provide guidance on:

- Component compatibility and sizing

- System balance and performance optimization

- Risk mitigation during installation and commissioning

- Long-term operational planning

This consultative approach transforms used equipment sourcing into a strategic advantage.

Building Confidence into Every System

For sophisticated buyers and consultants, used industrial refrigeration equipment offers an opportunity to build high-performing systems without the constraints of new equipment pricing and lead times. When compressors and condensers are selected, inspected, and integrated with system-level intent, the result is a reliable, efficient refrigeration solution built for long-term operation.

The key is working with partners who understand not just the components, but the system as a whole.

Refrigeration Equipment Professionals (REP) is a trusted supplier of industrial refrigeration systems and surplus/used equipment, offering compressors, chillers, condensers, evaporators, ice machines, freezers, coolers, pumps, motors, complete plants, and services like purchasing, refurbishing, shipping, export crating, and storage/consignment support. With 25+ years of experience and clients across North America, Latin America, the Middle East, and Asia, we deliver reliable, cost-effective refrigeration solutions worldwide.